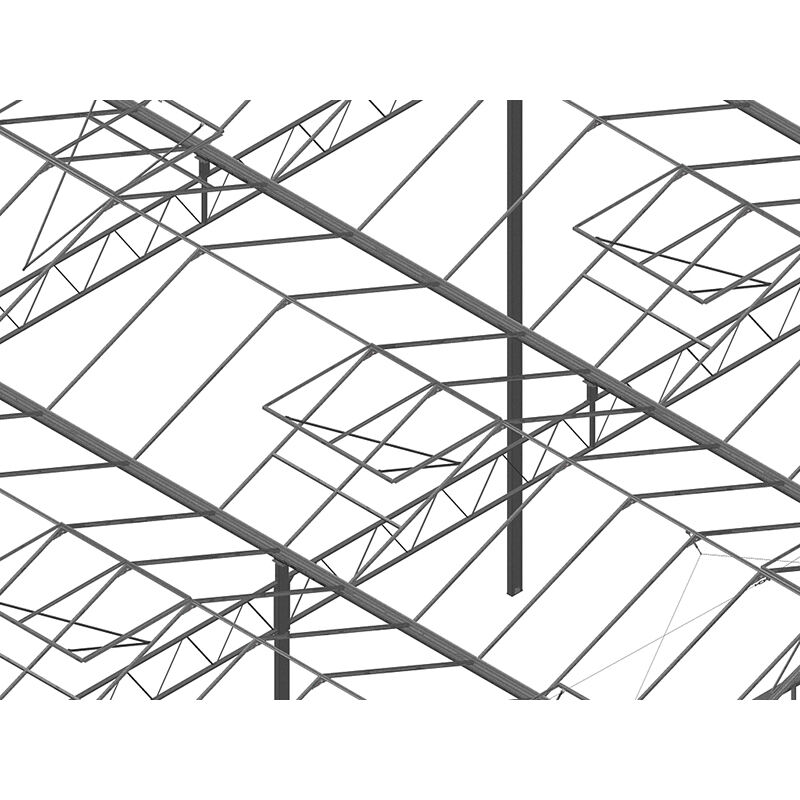

Конструкция от алуминиев сплав за градина

Въведение в обработката и използването на алуминиеви подпирни ролки за стъклени парници

- Преглед

- Свързани продукти

Преглед

1. Общ преглед

Подпорни ролкери от алуминиев сплав за стъклени гринхаусове са основен елемент на системата за отваряне на прозорците на гринхауса, използвани главно за поддръжка и насочване при отварянето и затварянето на прозорците. Качеството на обработката и характеристиките директно влияят върху ефективността на вентилацията на гринхауса и неговия срок на служебна годност.

2. Избор на материал

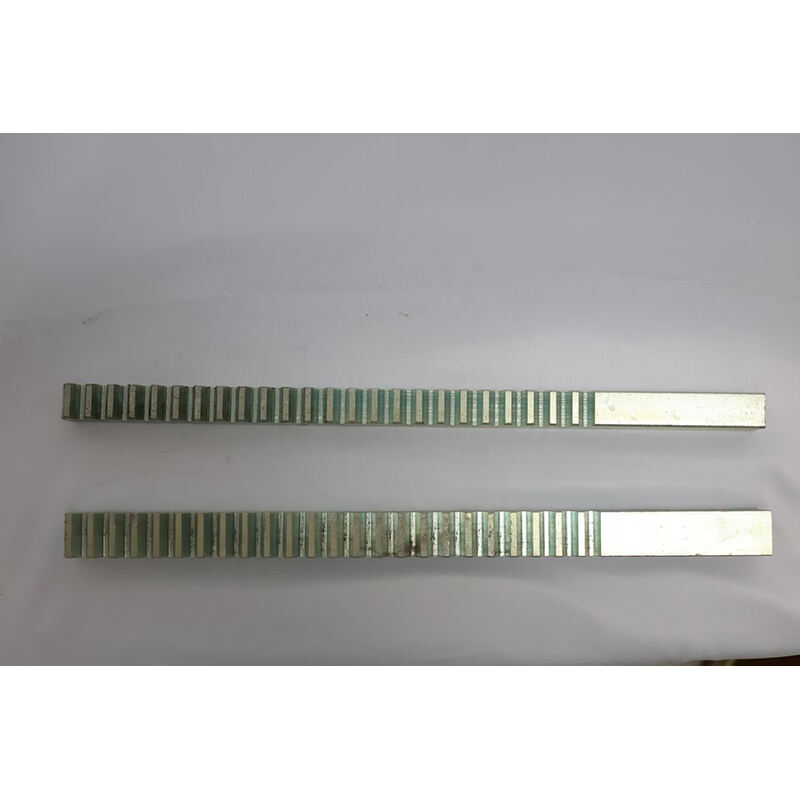

Тяло на колелце: Често се използват нейлон или полиуретанови материали, които са износостойки, корозионностойки и самолюbrtcящи.

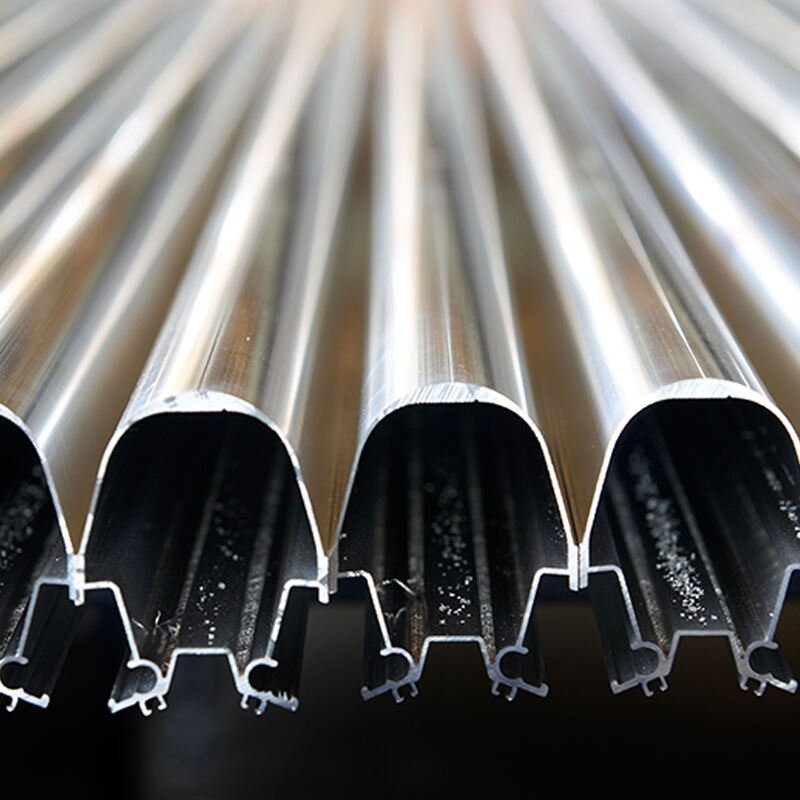

Конструкция: Използват се профили от алуминиев сплав, които са леки, с висока твърдост и корозионностойки.

3. Процеси на обработка

Обработка на тялото на колелото: Използва се инжекционно формуване за обработката на нилонови или полиуретанови материали в необходимата форма и размер на тялото на колелото.

Обработка на кронштейна: Чезване, борзане, нараняване и други процеси се използват за обработката на алуминиеви сплавни профили в необходимата форма и размер на кронштейна.

Монтаж: Тялото на колелото и кронштейнът се монтират заедно, за да образуват пълен опорен ролкера.

Качествена проверка: Монтираните опорни ролкери се проверяват по размери, външен вид, врътенчестост и капацитет за носене на тегло.

Упаковка и транспортиране: Квалифицираните опорни ролкери се упаковат и се вземат необходимите защитни мерки, за да се гарантира, че няма да бъдат повредени по време на транспортирането.

4. Инструкции за употреба

Инсталация: Според проектните изисквания на системата за отваряне на прозорците на градината, инсталирайте опорните ролкери на рамката на градината и прозорците.

Настройка: Настроете позицията и ъгъла на поддръжващите ролкери, за да се гарантира гладко отваряне и затваряне на прозорците без заклигане.

5. Предпазни мерки

Изберете модела и спецификациите на поддръжващата ролка, които отговарят на системата за отваряне на прозорците в гринхауса.

Постигнете надеждно и сигурно свързване на поддръжващата ролка с рамката на гринхауса и прозорците по време на инсталирането.

Регулярно поддържайте и обслужвайте поддръжващите ролкери, за да продължите техния срок на служба.

6. Развивани тенденции

Висока прочност: Разработване на нови материали и конструкционни дизайни, за да се подобри носещата способност и срокът на служба на поддръжващите ролкери.

Ниско трение: Използване на нови смазващи материали и технологии, за да се намали коефициентът на трение на поддръжващите ролкери и да се подобри гладкото отваряне и затваряне на прозорците.

Интелигентност: Интегрирайте датчици, контролери и други интелигентни устройства в поддръжващите ролкери, за да се постигне автоматично управление на отварянето и затварянето на прозорците.

EN

EN