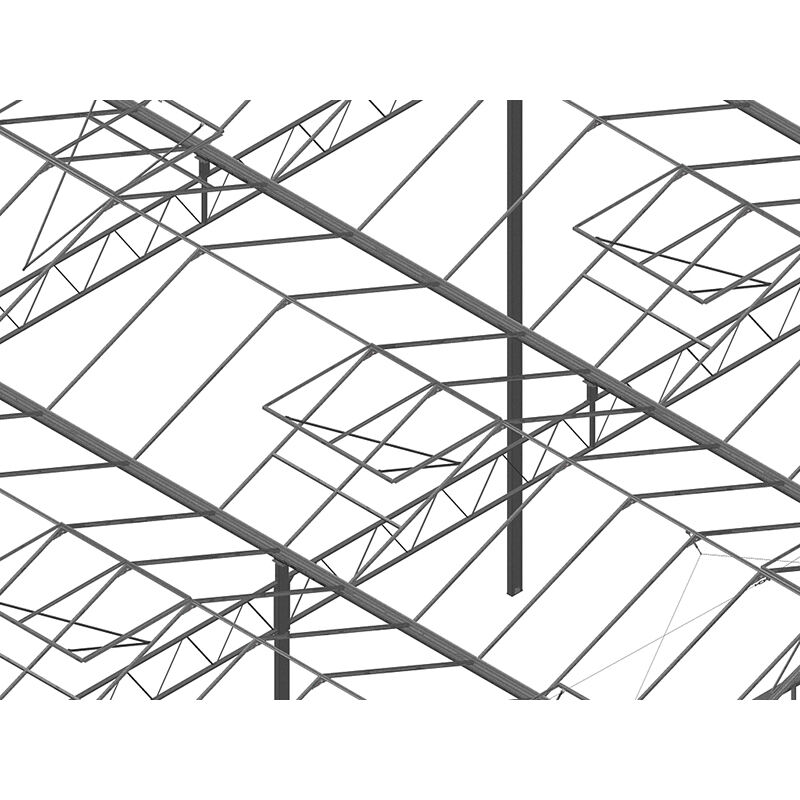

Greenhouse steel structure system

Introduction to the Processing of Aluminum Alloy Windows for Glass Greenhouses

Aluminum alloy windows for glass greenhouses are an indispensable part of greenhouse construction, and their processing quality directly affects the performance and service life of the greenhouse. Below is a brief introduction to the processing of aluminum alloy windows for glass greenhouses:

- Overview

- Related Products

Overview

1. Material Selection

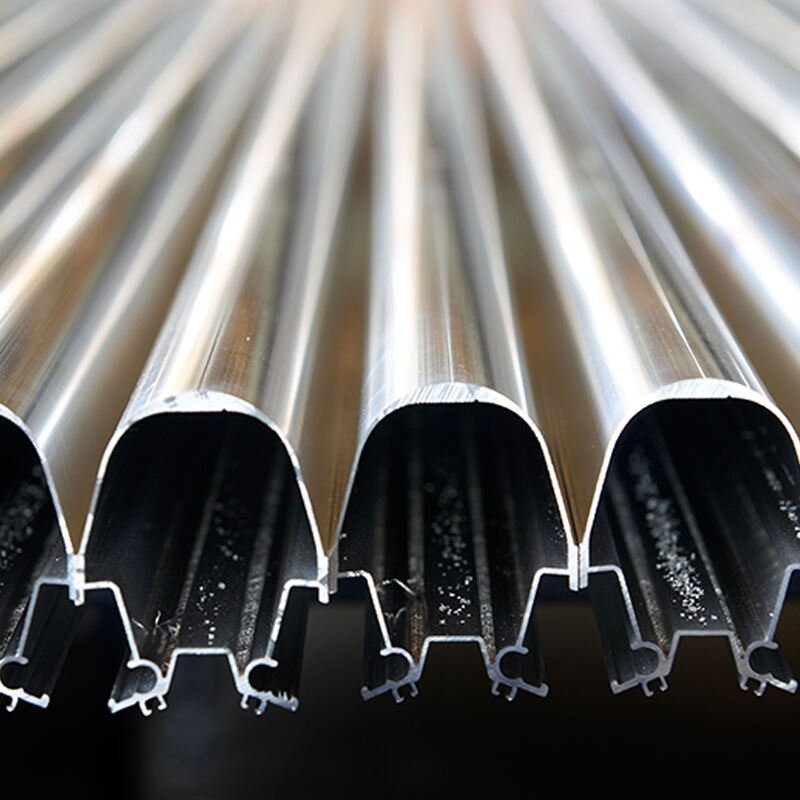

Aluminum Alloy Profiles: 6063-T5 aluminum alloy is usually selected, which has the characteristics of high strength, corrosion resistance, and easy processing. The wall thickness of the profiles is chosen according to the window size and load-bearing requirements, with common thicknesses ranging from 1.2mm to 2.0mm.

Glass: Tempered glass, hollow glass, or laminated glass is commonly used, which has good light transmittance, thermal insulation, and safety. The glass thickness is selected according to climatic conditions and thermal insulation requirements, with common thicknesses ranging from 4mm to 6mm.

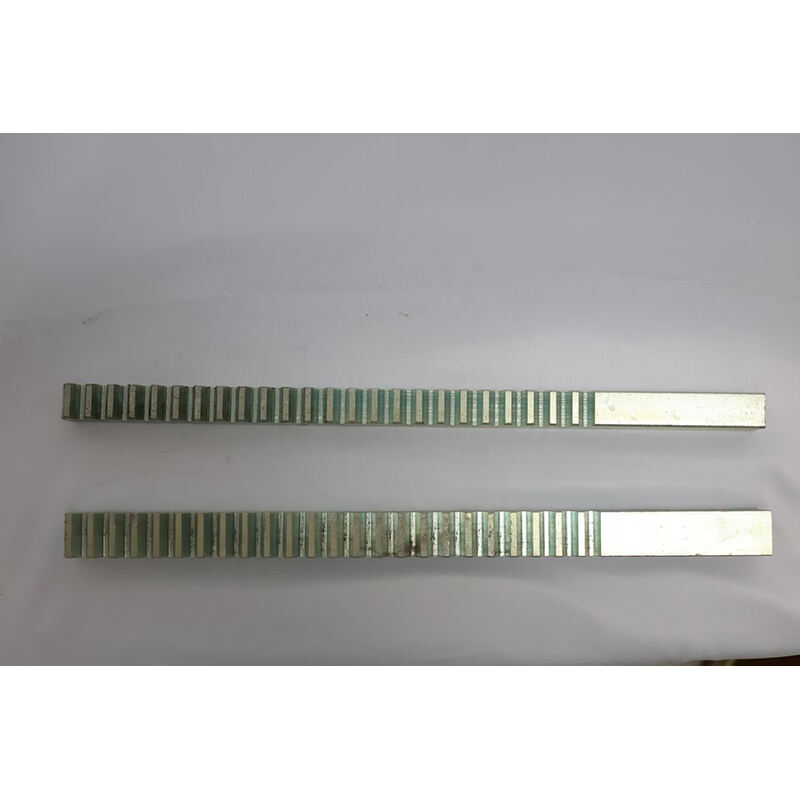

Sealing Materials: Ethylene-propylene-diene monomer (EPDM) rubber sealing strips are used, which have excellent weather resistance, aging resistance, and sealing performance.

Hardware Accessories: Including hinges, handles, rollers, etc., high-quality products with corrosion resistance and high strength should be selected.

2. Processing Procedures

Profile Cutting: According to the design drawings, aluminum alloy profiles are cut to the required length using a double-headed saw or a CNC cutting machine.

Profile Processing: Drilling, milling grooves, tapping, and other processing are carried out on the profiles to facilitate the installation of glass and hardware accessories.

Glass Cutting: According to the window size, glass is cut into the required shape and size using a glass cutting machine.

Glass Edging: The edges of the glass are ground to eliminate sharp corners and prevent scratches.

Window Frame Assembly: The processed profiles, glass, sealing strips, and hardware accessories are assembled according to the design drawings.

Quality Inspection: The assembled windows are inspected for dimensions, appearance, airtightness, and opening flexibility.

Packaging and Transportation: Qualified windows are packaged and necessary protective measures are taken to ensure they are not damaged during transportation.

3. Processing Equipment

Double-headed saw/CNC cutting machine

End milling machine

Copy milling machine

Corner forming machine

Glass cutting machine

Glass edging machine

Press

4. Precautions for Processing

Strictly control the cutting precision of the profiles to ensure accurate dimensions after window frame assembly.

Pay attention to safety during glass cutting and edging to prevent glass breakage.

Ensure that the sealing strips are properly installed during window frame assembly to guarantee the airtightness of the windows.

Hardware accessories should be installed firmly and reliably to ensure flexible window opening.

5. Development Trends

Intelligentization: Integrate sensors, controllers, and other intelligent devices into the windows to achieve automatic opening, closing, and ventilation functions.

Energy-saving: Use low-emission glass, thermal insulation profiles, and other materials to improve the thermal insulation performance of the windows and reduce energy consumption.

Lightweight: Develop new aluminum alloy materials and structural designs to reduce the weight of the windows and lower material costs.

EN

EN